Fashion, Tariffs and Confusion

A Designer, a Political Advisor and a Clothing Manufacturer Weigh In

While scrolling through my feeds last week, I noticed some understandable confusion about how tariffs will impact fashion. Don’t we want to bring back clothing manufacturing? Wouldn’t making it more challenging to purchase pieces made in Vietnam, Bangladesh, and Sri Lanka help bring the murky supply chain to the United States, where we can regulate it? Wouldn’t tariffs slow down consumption and ultimately fast fashion?

These are all fair questions, but they don’t have straightforward answers. But to start, let’s get this out of the way: reshoring clothing manufacturing would be a good thing IF we had the investment to do it correctly. An unfortunate byproduct of globalization is that the vast majority of clothing manufacturing has moved outside of the United States. The thriving factories in the 20th century are either gone or need serious retooling - that will cost money and government investment.

Moreover, factories in the United States are not necessarily a beacon of fair labor - often, it’s quite the opposite. In Los Angeles, where many fast fashion brands are already producing, garment workers report wage theft, abuse, and neglect regularly. Even after a new law was passed in California to make it easier for these workers to report their factories, the United States Department of Labor found violations in 80% of its investigations, which covered data from more than 50 garment contractors. Outside of the U.S., in factories that aren’t so great, making clothing for brands that have consistently shown they will not prioritize their workforce, there is a risk that the cost of these tariffs will come from their wages.

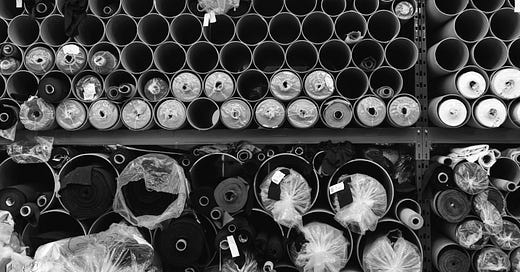

But not all factories are problematic, of course. Plenty of sustainable brands are manufactured in China, Vietnam, and other places around the world - and some of the factories are at the forefront of change. Plus, the supply chain in fashion is complex, and fabrics, threads, leather, and hardware come from around the world—again, there is no infrastructure to replace that right now.

So yeah, it isn’t very clear how this will all shake out. That’s why I wanted to zoom in a little and ask three different people – a policy expert, a designer, and a factory owner –for their unique perspectives on the impact tariffs will have on the global fashion industry.

Kelsey Randall, Designer and Stylist

“It's hard to understate the negative impact of the tariffs on my clothing line of made-to-measure pieces. Although we handmake everything in NYC, all my raw materials are imported. The metal discs I use for my chainmail come from Canada. I import my fabrics from Asia or India (even fabric bought in the garment district of New York is 99% imported- so those prices will skyrocket!!), and all my embellishments and hardware come from China. You can't honestly imagine we are going to open up rhinestone factories in America?? It would take half a century to build out the kind of textile manufacturing infrastructure to make us even slightly competitive with China or India, and we lack the workforce to scale any serious mass-market garment production. In the meantime, the tariffs will drive up the price of goods for American brands... I am already bracing for the headache of recalculating all my prices once the effect of the tariffs is apparent.

Caitlin Rooney, Policy Expert and Political Advisor

“While at face value, these tariffs can appear likely to boost American manufacturing, the reality is that the United States lacks the existing infrastructure and workforce to scale domestic clothing and textile production. If the Trump administration truly wants to bring back US manufacturing, particularly in the fashion space, it needs to provide incentives directly. That means targeted grants and loans for workforce development, job training, and capital improvements, all while ensuring fair wages for a growing workforce. These tariffs address none of the current industry stress points and only further the potential for increased consumer costs.”

Alex Dabagh, Anybag founder and NYC Factory Owner

“The tariffs being imposed will increase the demand and market share for my family-owned factory in NYC. It’s definitely going to create opportunities for my business to grow further and expand. Our “Made in USA” status and established reputation will become a stronger selling point against pricier imports. However, increased costs for imported raw materials and potential retaliatory tariffs pose significant risks to consider.”